Adventures in 3D printing PVC - Part 1

22 Jan 2017For my first blog post, I thought I’d write about the project which took up most of my time in my final year of undergrad.

During my third year internship, one thing kept popping up in my mind - what the hell was I going to do for my final year project? Rumour had it that lecturers offered a limited number of projects to students without one every year, and that preference was given to students with better grades. While I wasn’t concerned about my grades, they were also fairly middle-of-the-pack for my class. It was clear I had to come up with something, and fast.

Working in the lab, I’d look over my co-workers’ shoulders whenever I wasn’t busy with something else. I got to see a lot of cool materials I wouldn’t have gotten to see otherwise this way - different grades of latex, natural rubber, PVC and silicone, among others. Eventually I noticed something interesting about the way plasticised PVC behaves. You see, it starts life as a mixture of a particulate PVC resin, liquid plasticiser and heat stabilisers, as well as a few other components. Without any external colourants added to the mix, it’s a milky liquid, slightly runnier than cream. When you start to warm the mixture up, the plasticiser and the PVC begin to react with each other, and the mixture gels. The speed of this reaction varies based on the temperature and the exact ingredients used. This property is useful for slush moulding or dip coating - you can use a hot mould and dip it into a vat of PVC, and the material will deposit on the mould, giving a nice smooth coating.

The magic happens when you keep warming the PVC. After it has finished gelling it begins to melt like a thermoplastic. Provided it’s not overheated and begins to decompose, the PVC isn’t any worse for wear afterward - it looks and feels indistinguishable from the conventionally-made material.

I began to think that if I went about it the right way, I could modify a regular RepRap-style printer to print with soft PVC.

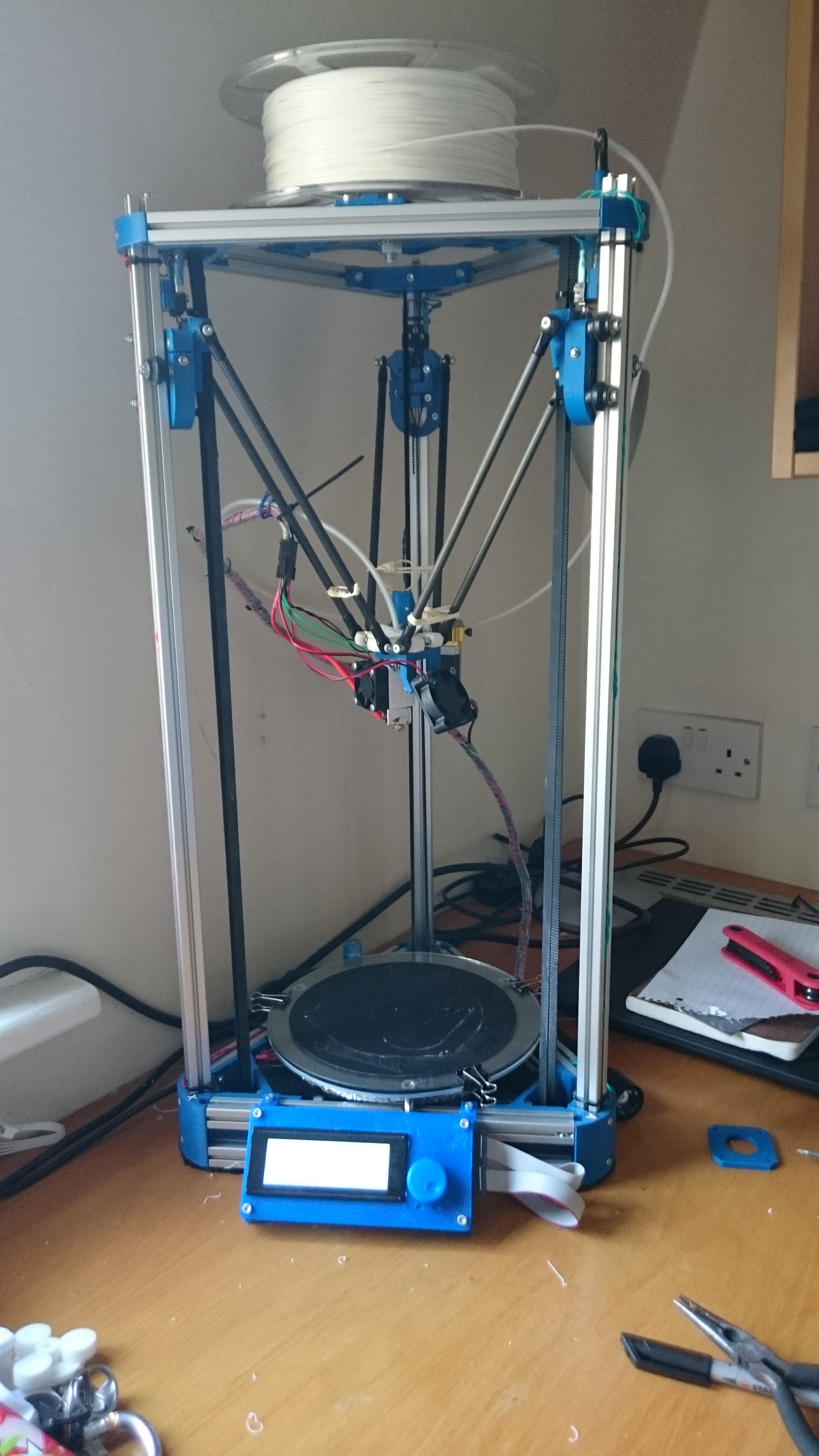

Having convinced my lecturers that I was confident I could pull this off, I started the project… by buying my first 3D printer. I’d had my eye on Think3DPrint3D’s Kossel Mini for a while, and this was the perfect excuse to buy one.

See my next few posts on how I got the system working.

Here’s a teaser:

And another: